Trusted by largest brands in India

Enterprise Solutions Overview

Comprehensive Business Technology Platform

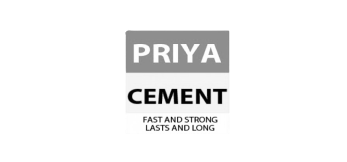

Conveyor Idlers Key Specifications

{context.products.key_specification_description}

Diameter Range (mm)

63.5, 76.1, 88.9 (Light) / 101.6 to 133 (Common) / up to 193.7 (Heavy Duty)

Duty Classes (CEMA)

Class I & II (Light) to Class V (Extra Heavy Duty)

Shaft Sizes

20mm to 35mm reinforced steel shafts

{context.products.variation_description}

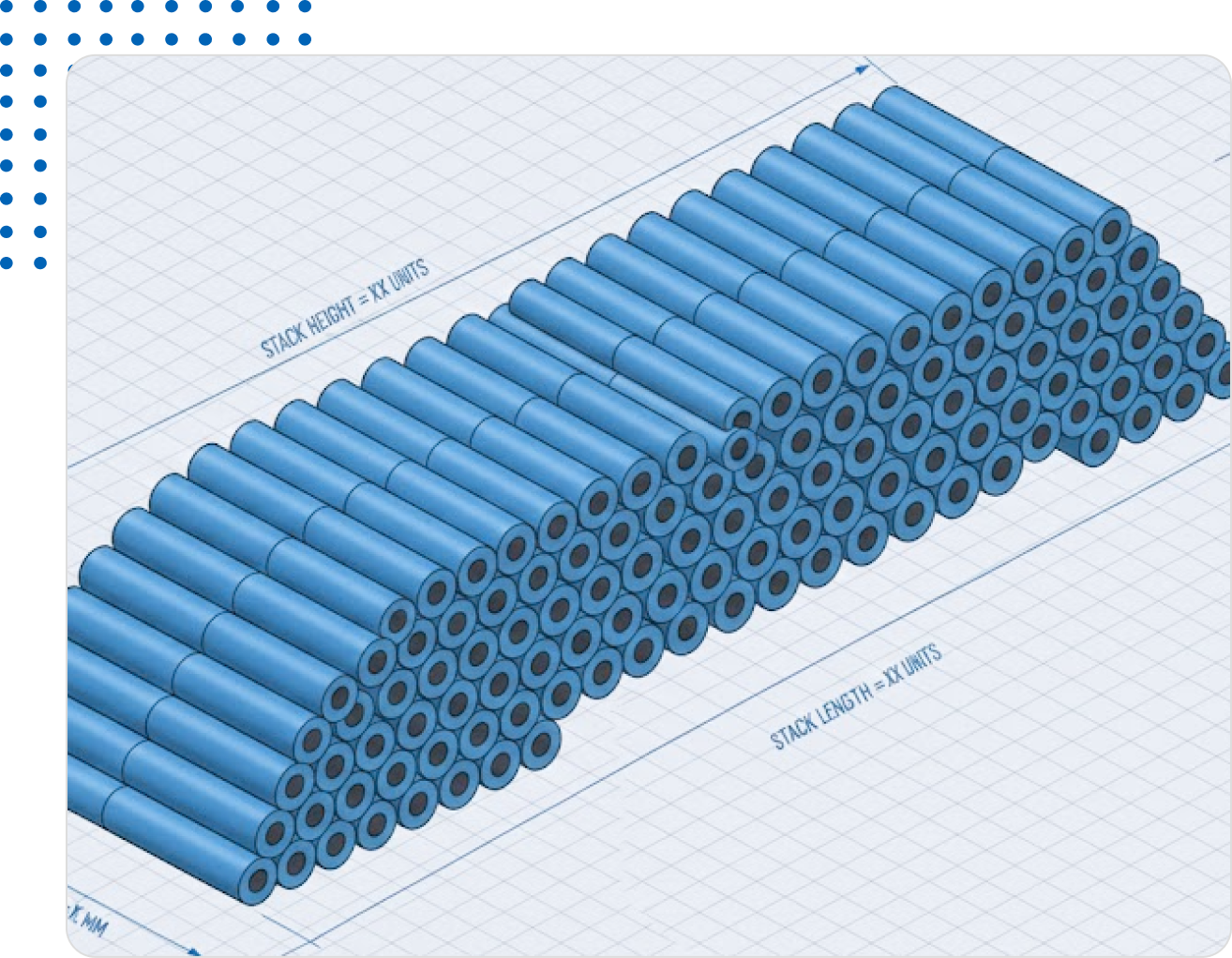

Impact Idler

Absorbs heavy shock loads at material loading and transfer points.

Troughing Idler

Supports the carrying side of the belt for stable bulk transport.

Return Idler

Supports the return belt and maintains belt tracking.

Conveyor Idlers Variations

01

Carrying Idlers

The primary support system for the loaded side of the belt, designed to maintain the "trough" shape and prevent material spillage during transport.

01

Return Idlers

Engineered to support the empty belt on its journey back to the tail pulley, ensuring the belt doesn't sag or create unnecessary friction.

01

Impact Idlers

Fitted with reinforced rubber rings to absorb the shock and energy of falling materials at loading points, protecting the belt from punctures and heavy wear.

01

Self-Aligning Idlers

Equipped with a pivoting mechanism that automatically detects belt wander and shifts to steer the belt back to the center of the conveyor frame.

01

Guide Idlers

Vertical rollers positioned on the sides of the conveyor to act as a physical fail-safe, preventing the belt from drifting too far and damaging the structure.

01

Garland Idlers

A flexible string of rollers linked together, ideal for high-speed, high-capacity lines where the conveyor must adapt to heavy load shifts or irregular terrain.

01

Spiral Idlers

Feature a unique corkscrew design that actively sheds sticky material and "cleans" the belt surface, significantly reducing carry-back and buildup.

01

Self-Cleaning Idlers

Specifically designed for wet or adhesive environments, using a specialized surface to prevent debris from hardening on the roller and causing belt misalignment.

01

Return Idlers with Rubber Discs

Utilize spaced rubber discs to break up material accumulation on the dirty side of the belt, protecting the return rollers from premature abrasion.

01

Idlers for Pipe Conveyors

Arranged in a hexagonal or circular configuration to wrap the belt into a sealed pipe shape, allowing for dust-free transport and tight curves.

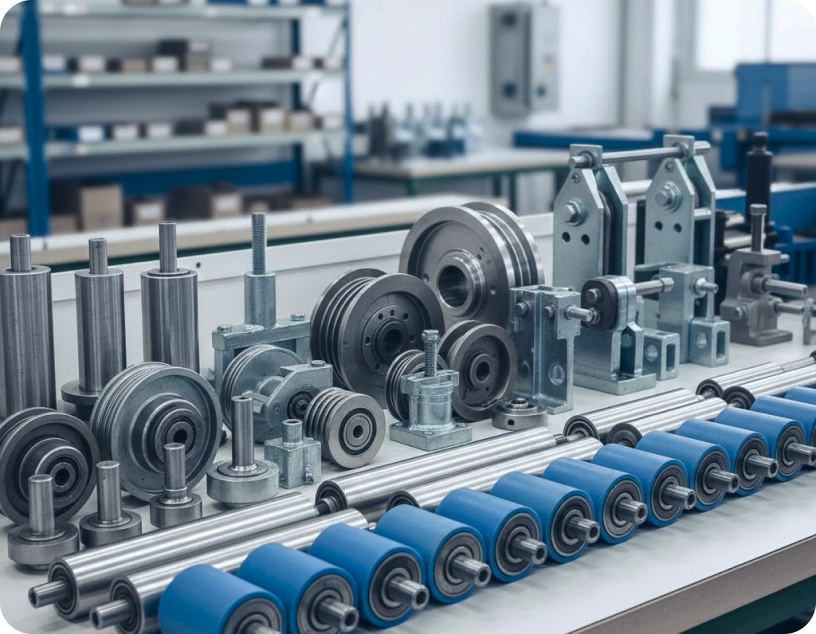

Industrial Applications

{context.products.use_case_description}

Core Features

Steel Industry

Iron ore, coke, limestone, finished steel transport

Integration

Agriculture

Grain elevators, feed mills, fertilizer handling

Security

Ports & Terminals

Bulk material ship loading/unloading

Conveyor Idlers for Industries

Cement Industry

Robust conveyors engineered for heavy-duty cement handling, ensuring seamless material flow from raw mix to final dispatch.

Patient Reviews

Customer Testimonial

I recently had the pleasure of working with United Global Engineering Solutions for our conveyor needs, and I must say I'm thoroughly impressed. Their expertise in conveyor systems, especially those designed for the food industry, is remarkable. The quality of their industrial conveyor belts is outstanding. Our operations have seen a significant improvement, and we're grateful for their support

We've been relying on United Global Engineering Solutions for multiple projects. Their conveyor belts for food processing are a game-changer. We appreciate their commitment to delivering high-quality products and their ability to customize solutions based on our specific needs. Their prompt service and cost-effective solutions are commendable.

We've been relying on United Global Engineering Solutions for multiple projects. Their conveyor belts for food processing are a game-changer. We appreciate their commitment to delivering high-quality products and their ability to customize solutions based on our specific needs. Their prompt service and cost-effective solutions are commendable.

We've been sourcing conveyor components from United Global Engineering Solutions for quite some time now. Their conveyor belt accessories, including industrial conveyor rollers and pulleys, have consistently met our quality and performance standards. We highly recommend them for all your conveyor system needs.

15+

Industries Served

10+

Years of Experience

500+

Systems Installed

600+

Happy Clients